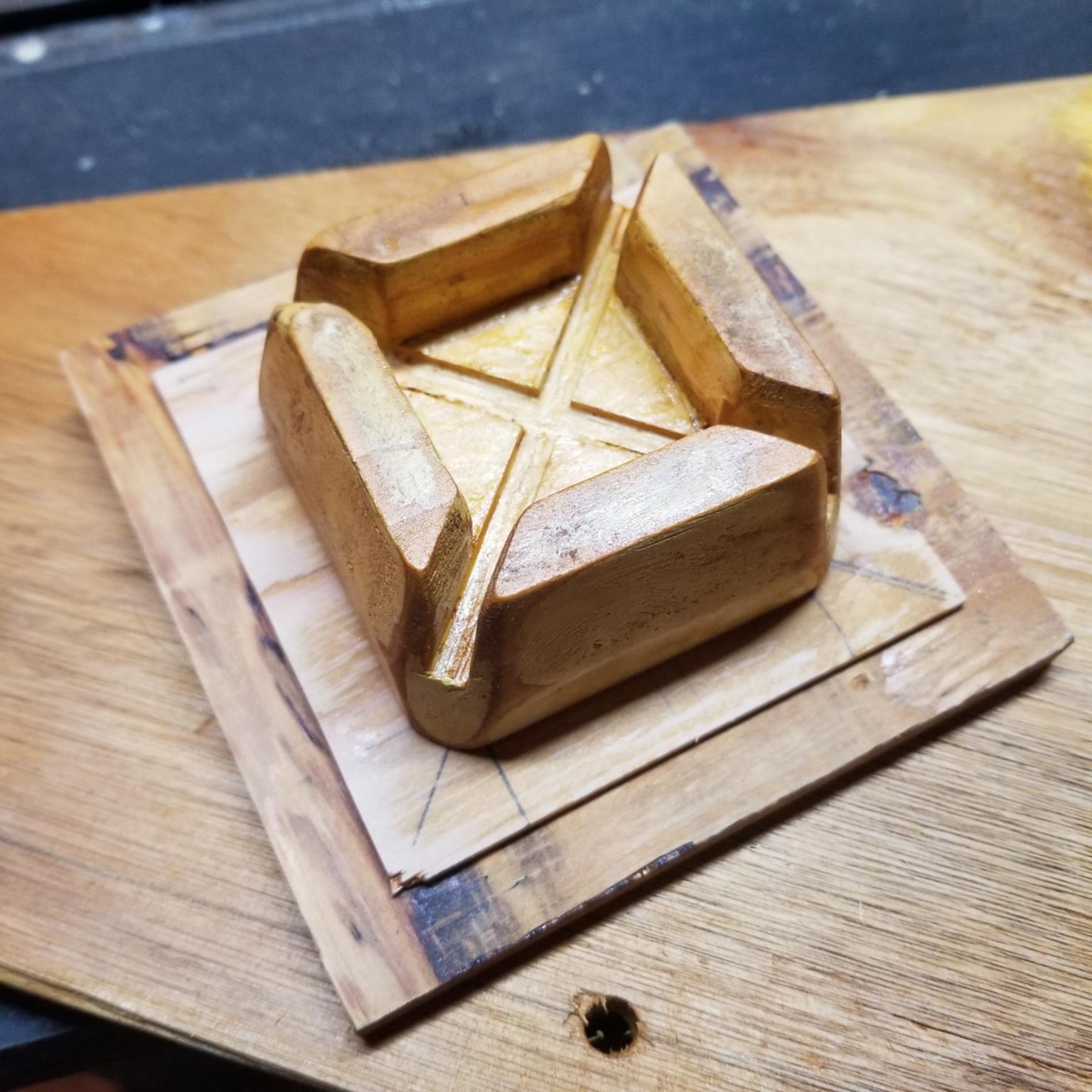

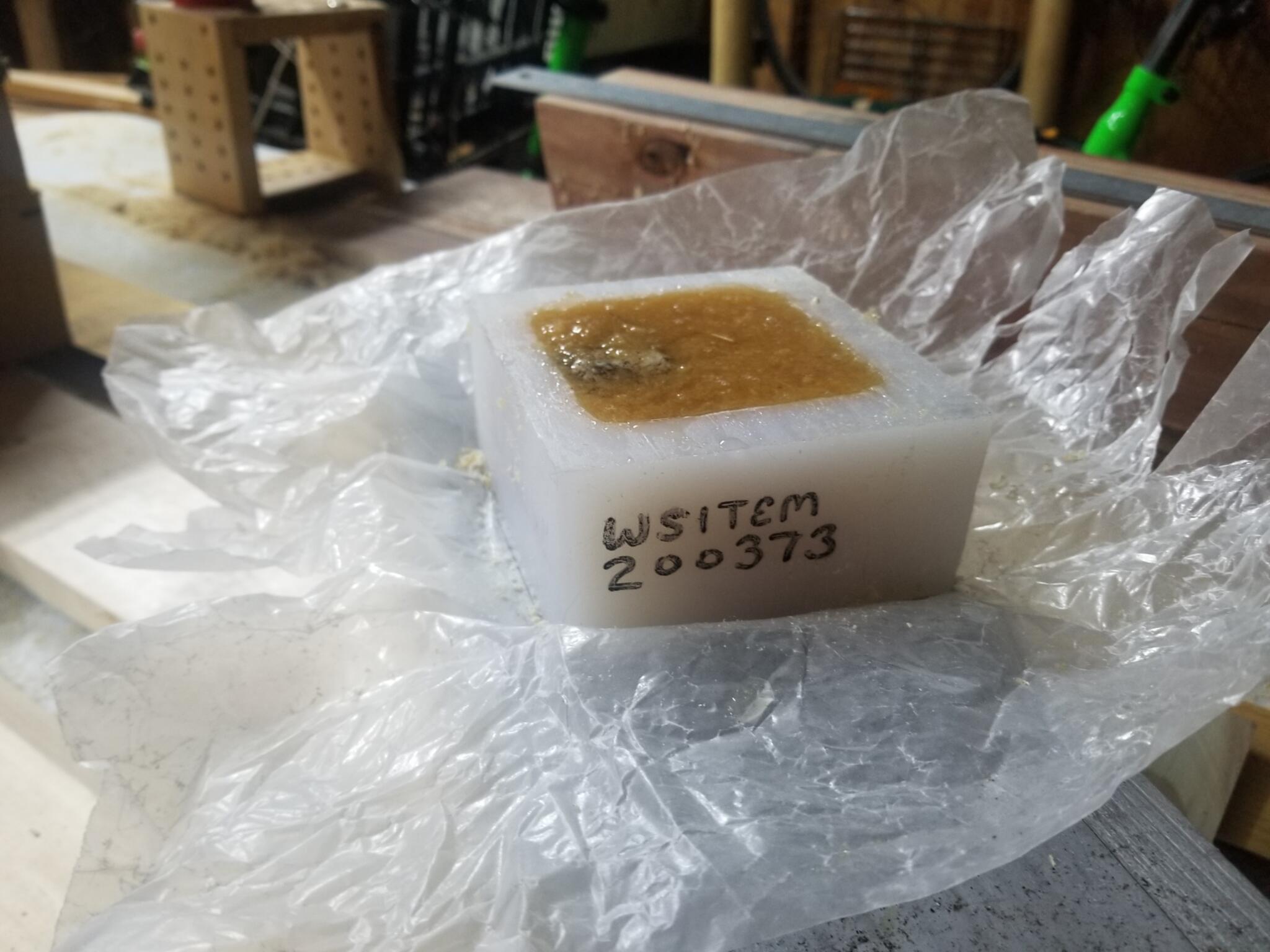

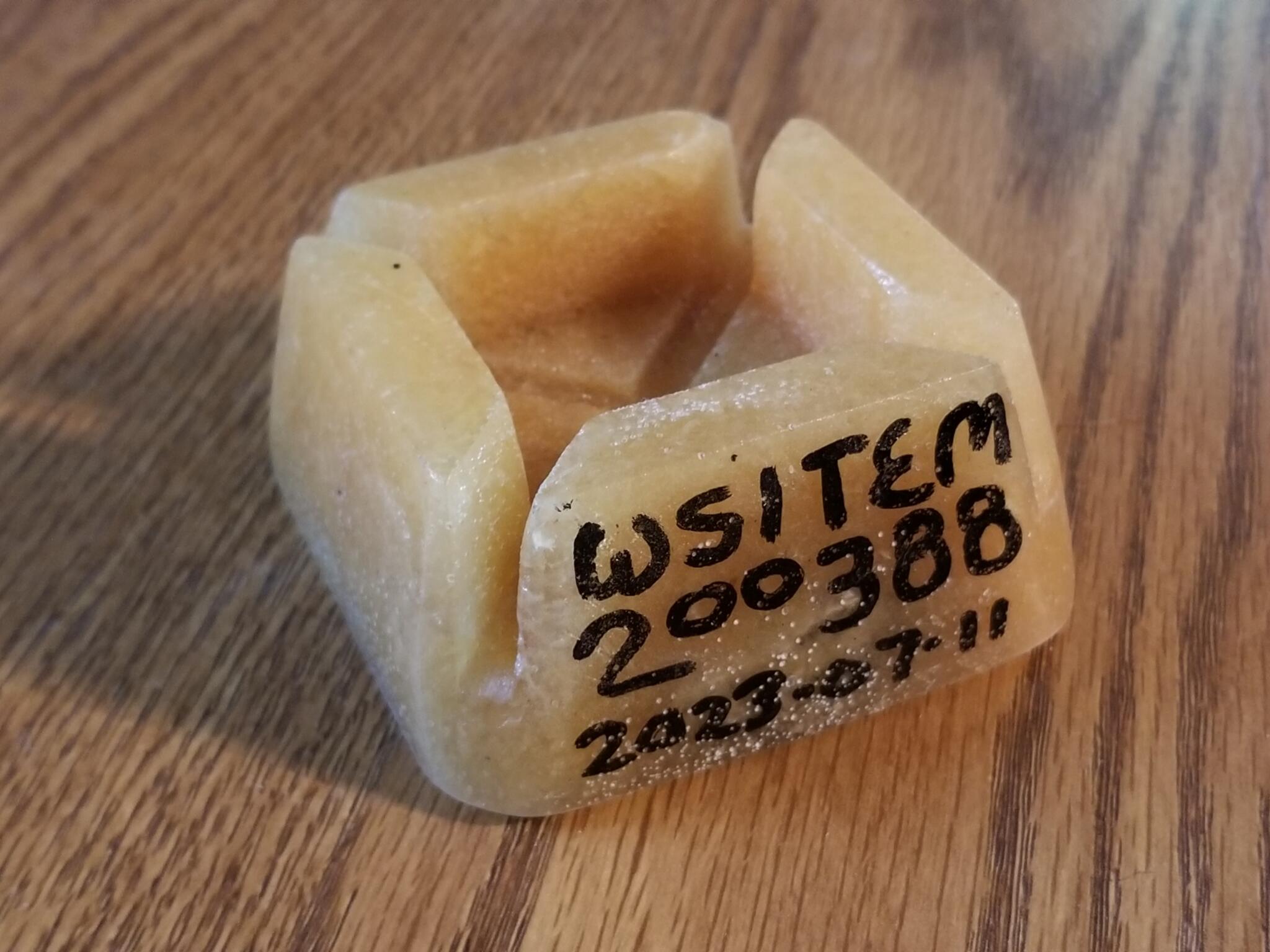

The Guerrilla guide to CNC and resin casting (which passed through HN a few months ago) inspired me to try resin-casting some stuff. For starters, I carved a 3″×3″×1½″ 'gridbeam foot' out of a section of two-by-four, made a mold of it using some silicone mold resin, let that sit in a box for a few months, and then finally sprayed it with mold release spray and poured some 'glaze coat' epoxy (the same stuff I've used in the past to embed LED strips into blocks of wood) into it. I hadn't mixed quite enough resin, so I shoved/mixed sawdust into the mold until the surface of the epoxy was about to the top of the mold. I also added a rock, which complicated things somewhat.

This was relatively successful, though the rock I had added protruded slightly from the bottom and had to be ground down. The sawdust is a nice touch, and in the future I might pre-mix it into the resin before pouring into the mold, but for purposes of adding volume it might be more useful to have a bucket of small rocks or other small but denser-than-epoxy, less-porus-than-sawdust chunks.